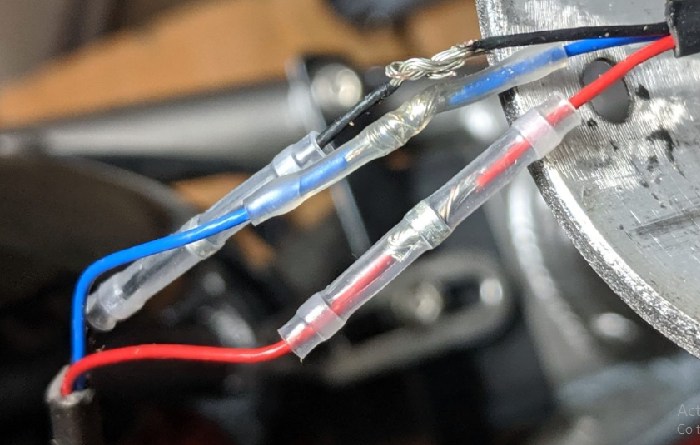

Butt splice connectors are used to join two or more wires or cables; it’s an electrical connector. Those looking for a quick and efficient way to connect wires might be interested in giving butt splice connectors a try. They frequently join wires securely and reliably without soldering in electrical and wiring applications.

These connectors are available in different wire gauge sizes to suit the applications. These connectors are available in different wire gauge sizes to suit the applications. Besides, being in different colors makes them easy to remember. It is used in many ways, like industrial, household wiring, electronics, and automotive.

If you’ve never used these particular connectors before, don’t worry; we’re going to break down some of the main advantages of using them, as well as how they work and other options that might be worth considering.

Table of Contents

How do Butt Splice Connectors Work?

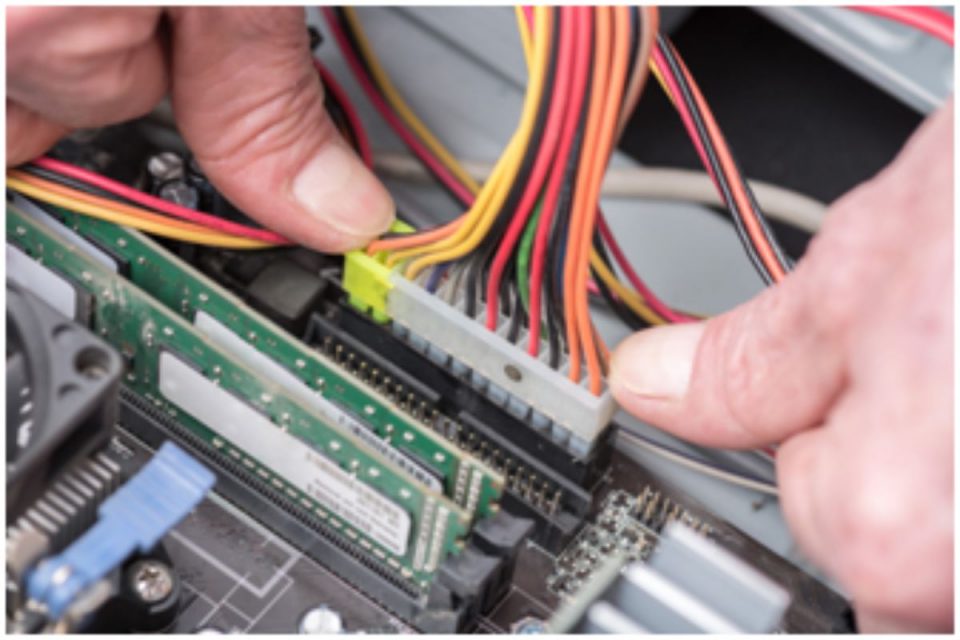

To connect wires with a butt splice connectors, all you need to do is push the wire into the connector and compress it with pliers or a crimping tool. Now that you’ve crimped the wire and connector together, the cable inside is forced to touch the metal. Next, the other end can be crimped to terminate the wire.

There are plenty of different ones to choose from, in different sizes, colors, and materials, making it easier to find the right ones for your needs. They’re easy to use, whilst also being safe and inexpensive at the same time.

They’re almost always a cylinder shape, with a crimp at each end for sealing. Some are made with heat shrinking ends instead, which you might find to be a better option depending on the task at hand. With all this, it shouldn’t be hard to see why these types of components are such a common choice.

Bootlace ferrules – Another Great crimp Connector

A bootlace ferrule is another excellent form of crimp connector, although there are a few differences between these and butt splices. These can have several advantages, particularly for bare stranded wire, helping to create a reliable and secure connection. With these particular components, you need to crimp the metal tube instead of the insulation.

What’s Better, Crimps or Soldering?

Despite their simplicity, crimping connectors are generally an excellent option, being as common as soldering in many cases.

While there’s no doubt that soldering has its advantages.There are definitely a few reasons why it might be worthwhile to try crimp connectors instead. Often, this is due to how easy and cheap they can be compared to soldering in general (which can be time-consuming and require a few more steps to get set up, too).

Are They Easy to Get Hold Of?

Fortunately, since so many people use them, they’re incredibly easy to find and purchase. Most electronic stores, both in-person and online, will stock them in their various styles and sizes and you can often get plenty for a low price – which is a nice bonus for such a useful accessory.

Conclusion

Always follow the manufacturer’s directions when using butt splice connections or other electrical components to ensure correct installation and performance. Call a skilled or experienced electrician or specialist if you have questions about utilizing butt splice connections or need help with a specific wiring job.